Event Rentals - Event Production in Miami, Broward, Palm Beach & Florida Keys

GET A QUOTE

GET A QUOTE

Master sound production is one of South Florida's top sources for event planners and concert event production setup.

Chain Motor Rental (also called electric chain hoists) for live events and can be configured in a variety of ways. Motors are always subject to the rigging diagram for a building or rooftop. we would create a diagram with the rigging points available for specific structure, ceiling or venue.

They also show the amount of weight that each rig point can hold. At In Depth Events, we have years of experience working with rigging diagrams. In fact, we create them for the load bearing rooftops that we own and provide rental services for.

When doing any kind of rigging, safety is the number one concern.

We work hard to make sure our rigging and motors are certified up to date and our spansets arrive with no rips or tears. Our motor controls are state of the art and we make sure that our motor cable and feeder runs arrive in the right lengths for your specific show.

To maintain our high level of service, we do NOT offer box rentals on our motors and rigging. However, we are happy to provide our riggers and stagehands along with our motors to make sure your rigging needs are taken care of appropriately!

FLEXIBLE USE FOR A VARIETY OF APPLICATIONS

H4 Duty makes hoist ideal for heavy-duty industrial applications.

RUGGED AND DEPENDABLE

Hardened, forged steel, latch type hooks and Hoistaloy load chain for long, dependable service. H4 duty standard. Rugged control station (NEMA 4X).

STANDARD FEATURES

Hoist duty motor, standard overload protection device and standard screw-type limit switches. Quick change voltage board-change from low voltage to high voltage by re-positioning the receptacle.

GEARING DESIGNED FOR LONG LIFE AND QUIET OPERATION

Gear train lifetime lubricated with non-oxidizing grease. Zinc-plated chain standard.

PRECISE LIFTING CONTROL

Precision machined and hardened liftwheel with hardened chain guides to ensure chain fits tightly and securely in liftwheel.

EASY TO INSTALL AND MAINTAIN

Quick, easy installation and operation. No special tools required to disassemble for simple maintenance and inspection.

ADDITIONAL INFORMATION

Lifetime warranty. Inspected and tested over 125% of rated load prior to shipment. Meets ASME B30.16. Metric rated. Made in USA.

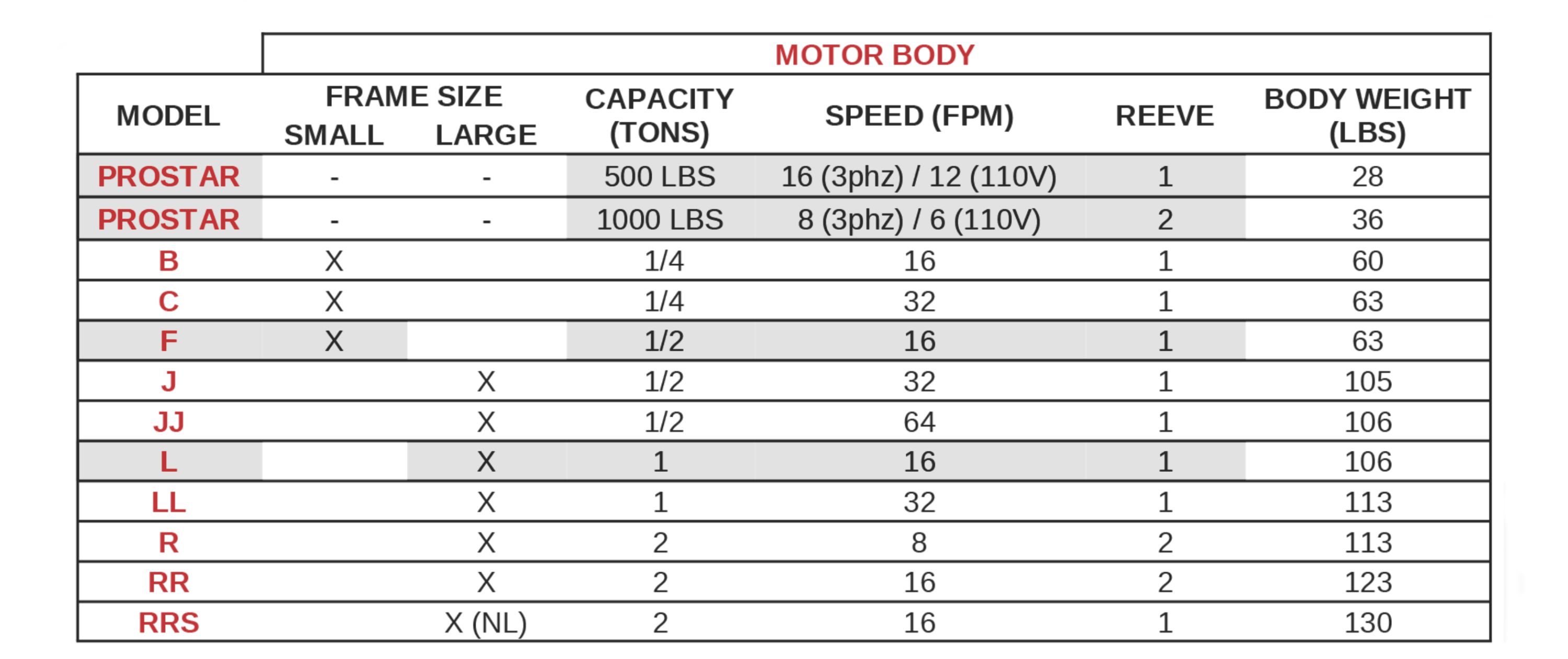

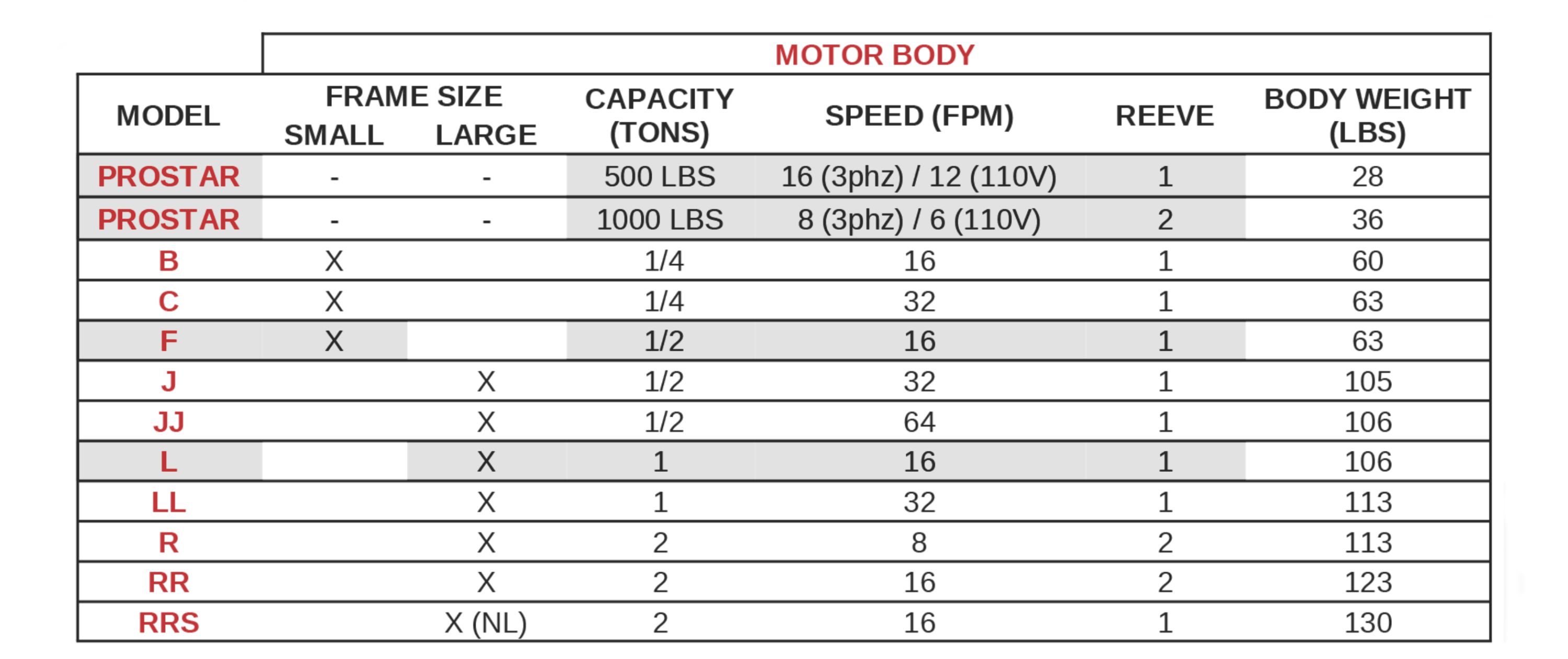

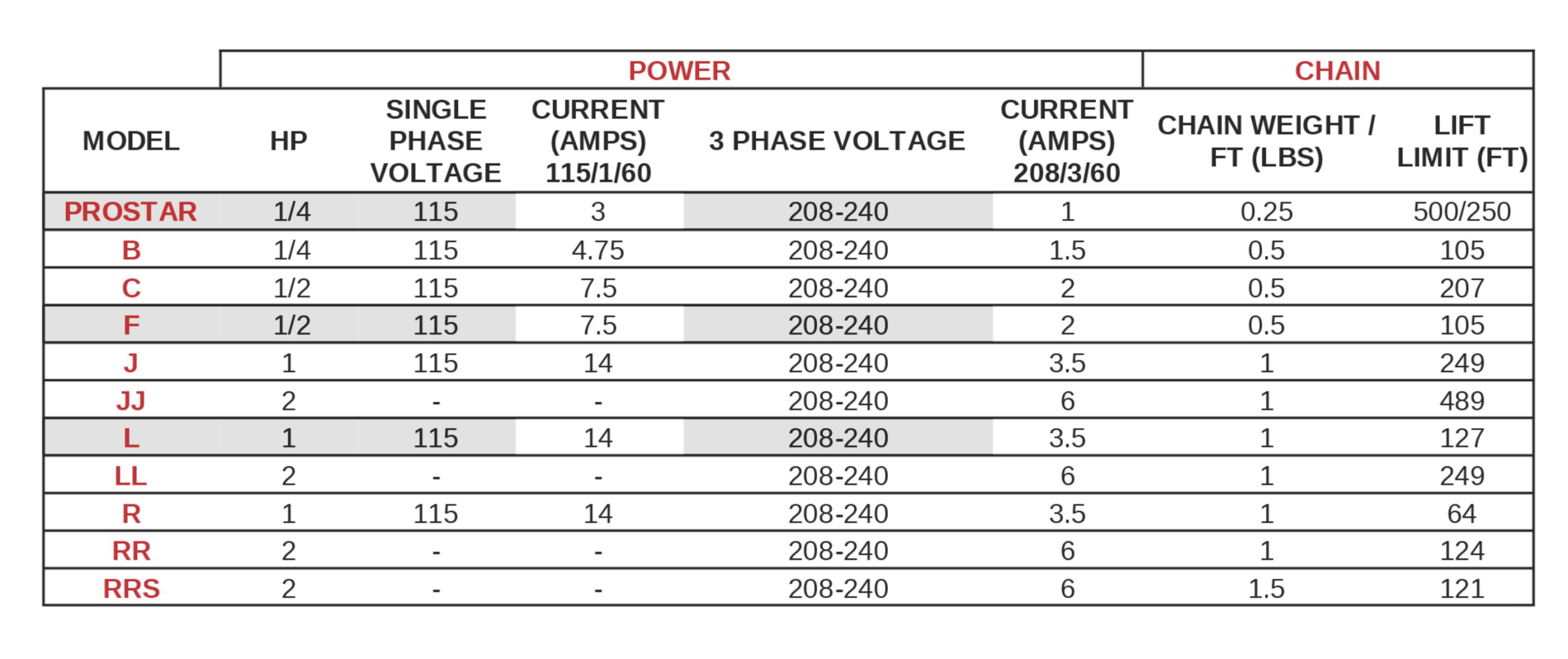

Click to enlarge

Click to enlarge

FLEXIBLE USE FOR A VARIETY OF APPLICATIONS

H4 Duty makes hoist ideal for heavy-duty industrial applications.

RUGGED AND DEPENDABLE

Hardened, forged steel, latch type hooks and Hoistaloy load chain for long, dependable service. H4 duty standard. Rugged control station (NEMA 4X).

STANDARD FEATURES

Hoist duty motor, standard overload protection device and standard screw-type limit switches. Quick change voltage board-change from low voltage to high voltage by re-positioning the receptacle.

GEARING DESIGNED FOR LONG LIFE AND QUIET OPERATION

Gear train lifetime lubricated with non-oxidizing grease. Zinc-plated chain standard.

PRECISE LIFTING CONTROL

Precision machined and hardened liftwheel with hardened chain guides to ensure chain fits tightly and securely in liftwheel.

EASY TO INSTALL AND MAINTAIN

Quick, easy installation and operation. No special tools required to disassemble for simple maintenance and inspection.

ADDITIONAL INFORMATION

Lifetime warranty. Inspected and tested over 125% of rated load prior to shipment. Meets ASME B30.16. Metric rated. Made in USA.

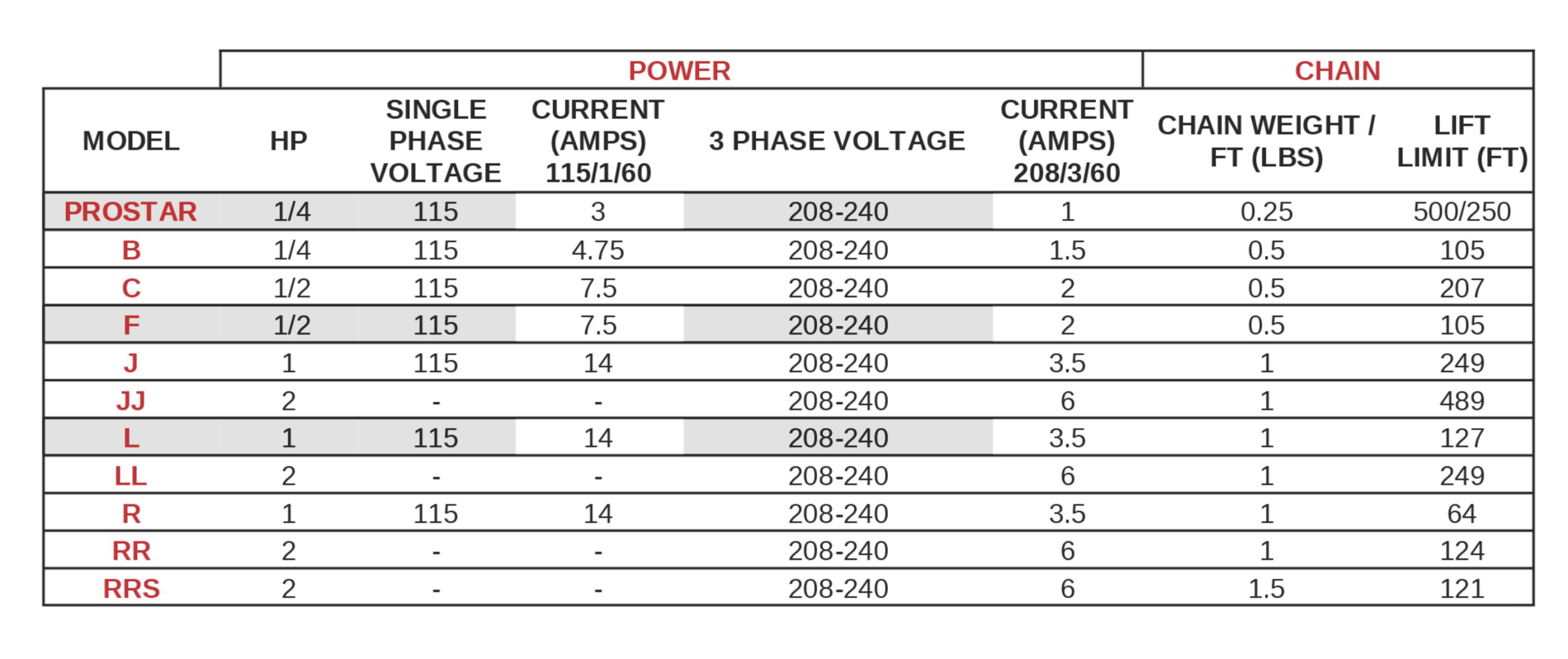

Click to enlarge

Click to enlarge

FLEXIBLE USE FOR A VARIETY OF APPLICATIONS

H4 Duty makes hoist ideal for heavy-duty industrial applications.

RUGGED AND DEPENDABLE

Hardened, forged steel, latch type hooks and Hoistaloy load chain for long, dependable service. H4 duty standard. Rugged control station (NEMA 4X).

STANDARD FEATURES

Hoist duty motor, standard overload protection device and standard screw-type limit switches. Quick change voltage board-change from low voltage to high voltage by re-positioning the receptacle.

GEARING DESIGNED FOR LONG LIFE AND QUIET OPERATION

Gear train lifetime lubricated with non-oxidizing grease. Zinc-plated chain standard.

PRECISE LIFTING CONTROL

Precision machined and hardened liftwheel with hardened chain guides to ensure chain fits tightly and securely in liftwheel.

EASY TO INSTALL AND MAINTAIN

Quick, easy installation and operation. No special tools required to disassemble for simple maintenance and inspection.

ADDITIONAL INFORMATION

Lifetime warranty. Inspected and tested over 125% of rated load prior to shipment. Meets ASME B30.16. Metric rated. Made in USA.

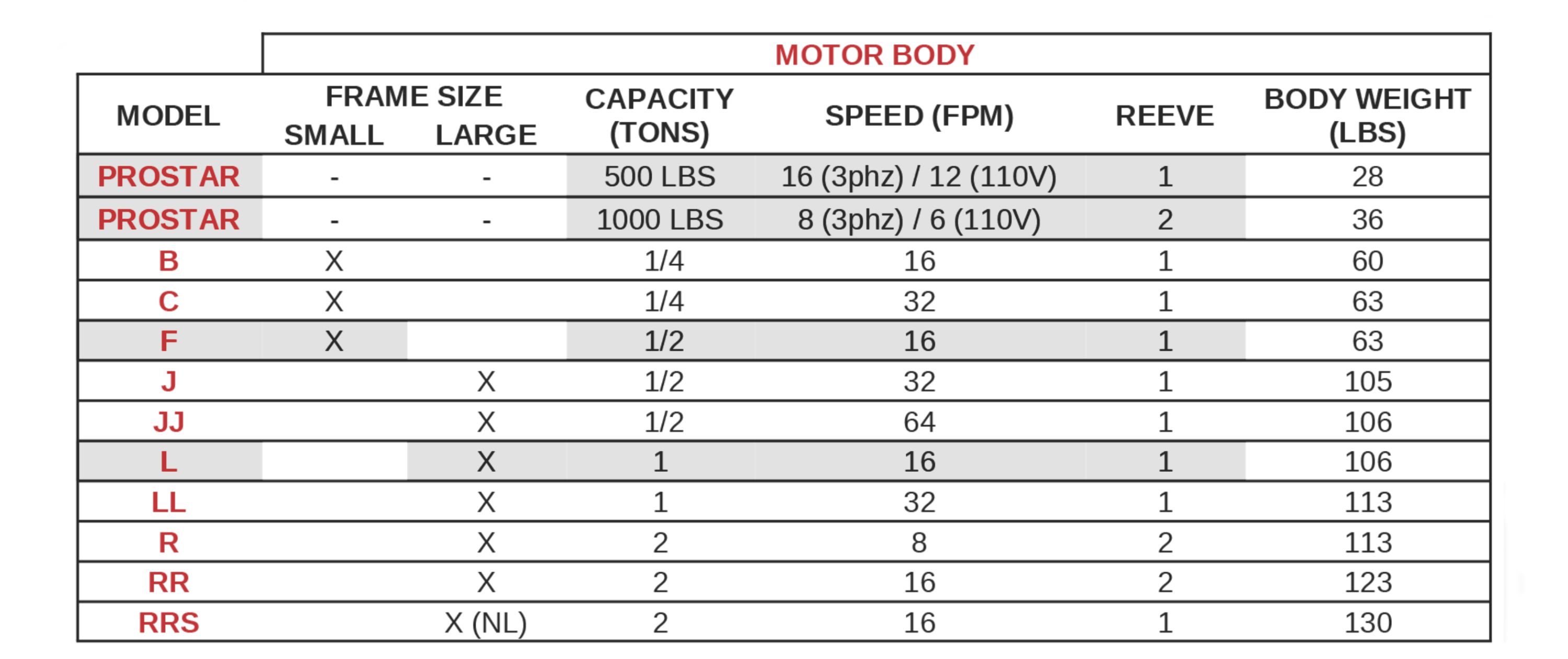

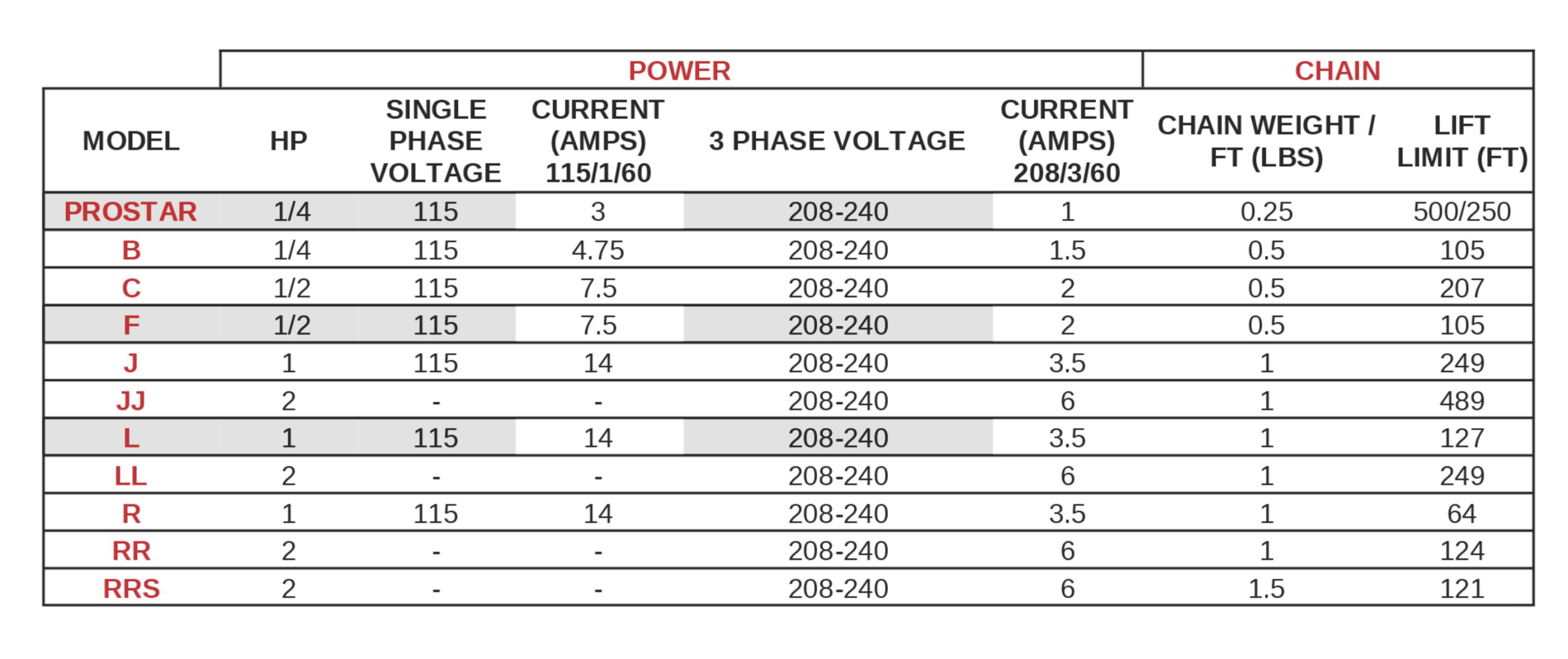

Click to enlarge

Click to enlarge

The Applied 65’ x 45’ Peaked Ladder Roof system is constructed with 20.5” x 30” spigoted truss for the perimeter and heavy-duty ladders for the interior grid. This type of construction provides multiple rated pick points across the grid. The towers are 16” x 16” tower truss at 45’. This roof can be supplied with or with-out sound wings. The Applied 65’ x 45’ roof system is raised to trim height with electric chain motors. All Applied roof systems comply with ANSI E1.21-2013, Entertainment Technology Temporary Structures Used for Technical Production of Outdoor Entertainment and include a third-party engineering report, operation management plan and a high wind action plan.